October 22, 2020

ECONYL® Regenerated Nylon Charts a Course for the Circular Economy

Reducing the global warming impact of nylon by 90 percent, ECONYL® by Aquafil rethinks product lifecycle.

Sponsored by:

For decades, architects and designers have generally approached sustainability goals by focusing on operational energy—energy consumed for heating, cooling, and lighting. But while building performance has become more efficient over the years, embodied carbon—the carbon footprint of a material, which considers the greenhouse gases released to produce it—has grown exponentially. “We need to think about designing products with their end in mind,” says Franco Rossi, president of Aquafil USA, which produces completely regenerated nylon carpet yarn from waste, called ECONYL® nylon. “Many times, that end is the landfill. So, what do you do with this information?”

According to Rossi, tackling the problem of material waste is a long-term effort, but a necessary one. Each year, four billion pounds of carpet—one of the primary uses for nylon—are discarded in landfills. About 11 billion square feet of carpet — which makes up 60 percent of the U.S. flooring market — is sold each year, yet only 5 percent of carpet waste is recycled. The problem, says Rossi, is that nylon is almost always mixed with other materials, making recycling extremely onerous.

In 2011, Aquafil committed to the task of producing nylon from waste instead of oil and launched ECONYL® nylon, a durable material that can be recycled an infinite number of times, without loss of quality. Sources of waste nylon—everything from fishing nets to textiles—are as varied as the material’s uses. A portion of what Aquafil recycles is made up of fishing nets, primarily coming from the aquaculture industry, but there is also a small portion retrieved from the ocean by teams of divers in partnership with the . Less glamorous but with greater potential impact are the massive quantities of discarded carpeting that Aquafil is able to recycle in its two new facilities in the United States. These plants recover disused carpets and disassemble them to transform the nylon components into ECONYL® nylon. , explains Rossi, “is indistinguishable from virgin nylon—they are chemically identical, except ECONYL® nylon reduces the global warming impact of nylon by up to 90 percent compared with material produced from oil.”

But Aquafil knows that this is just the beginning. The scale of our waste problem demands an industry-wide response. By partnering with designers to make products more sustainable and recyclable from the get-go, working with carpet suppliers to help them make sustainable choices, and working with recyclers to develop end-of-life solutions for nylon products, the effects of ECONYL® ripple out into the larger ecosystem.

For architects and designers, specifying materials with small carbon footprints, such as ECONYL® nylon, is integral to reducing a project’s embodied carbon, which was the focus of a recent Metropolis webinar titled “Designing a Circular Economy.” Considering the vast use of carpet in the building industry, choosing an ecologically responsible flooring product can have a meaningful impact on sustainability: For every 10,000 tons of ECONYL® nylon raw material, 70,000 barrels of crude oil are saved and 65,100 metric tons of CO2 equivalent emissions are avoided.

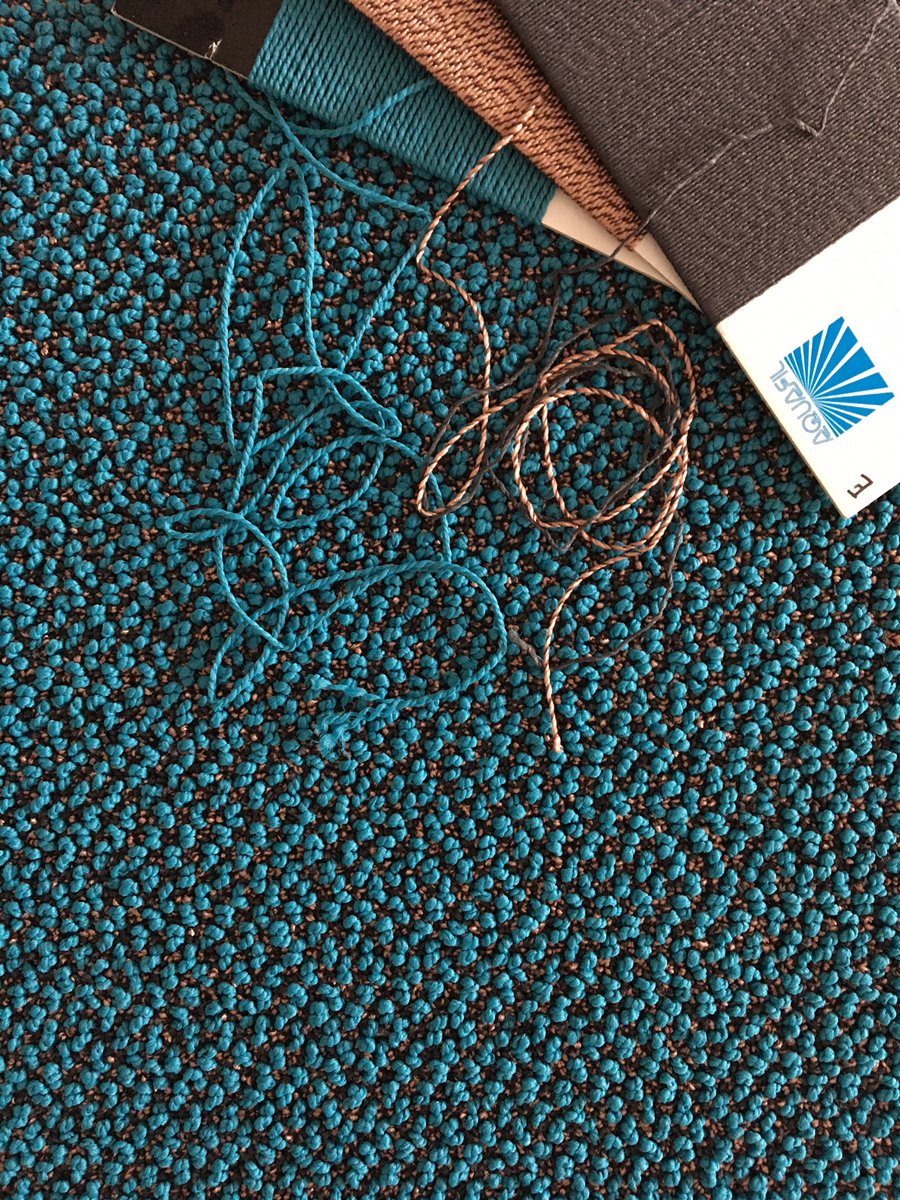

From the abstract patterns, versatile colors, and captivating textures of Masland Contract’s Crafted Collection, to the handcrafted look of Interface’s Thread Story collection, ECONYL® nylon yarns bring a crucial sustainable dimension products produced by over 1,000 brands.

Manufactured in facilities that run on 70 percent renewable energy resources, ECONYL® nylon represents Aquafil’s investment in moving toward a circular economy and away from the current “take, make, waste” model. It’s a system that revives natural ecosystems, creates value for people, and gives businesses a competitive edge, says Rossi. “If you feel good about doing the right thing, that motivation will lead you to a good product.”