April 19, 2022

LIVDEN’s Low-Impact Tiles are LEED-Ready

Would you like to comment on this article? Send your thoughts to: [email protected]

Related

Products

These Biobased Products Point to a Regenerative Future

Discover seven products that represent a new wave of bio-derived offerings for interior design and architecture.

Profiles

Chris Adamick Designs for Life

The Los Angeles–based product designer launches the paradigm-shifting Admix table system with Allsteel.

Profiles

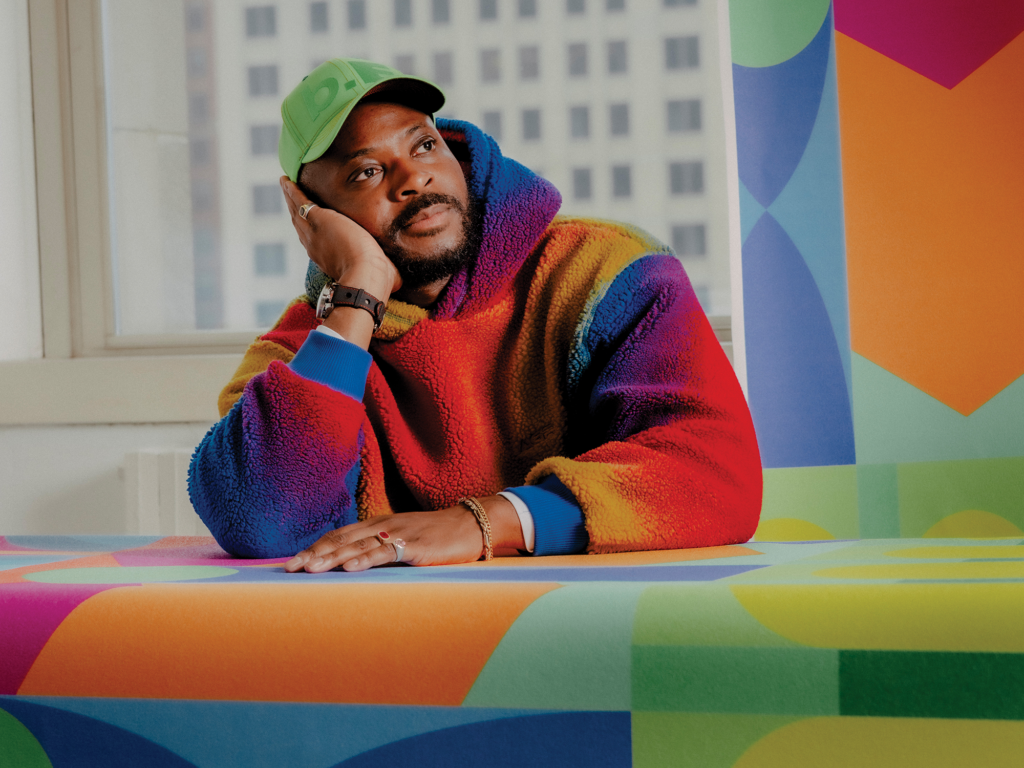

Designer Yinka Ilori Wants to Bring Joy to Work

Through colorful designs like his new collection produced with textiles and wallcoverings brand Momentum, the London-based designer hopes to unleash our creative potential in the office.