July 22, 2020

Tedlar® Film helps to Meet Increased Healthcare Cleaning Needs

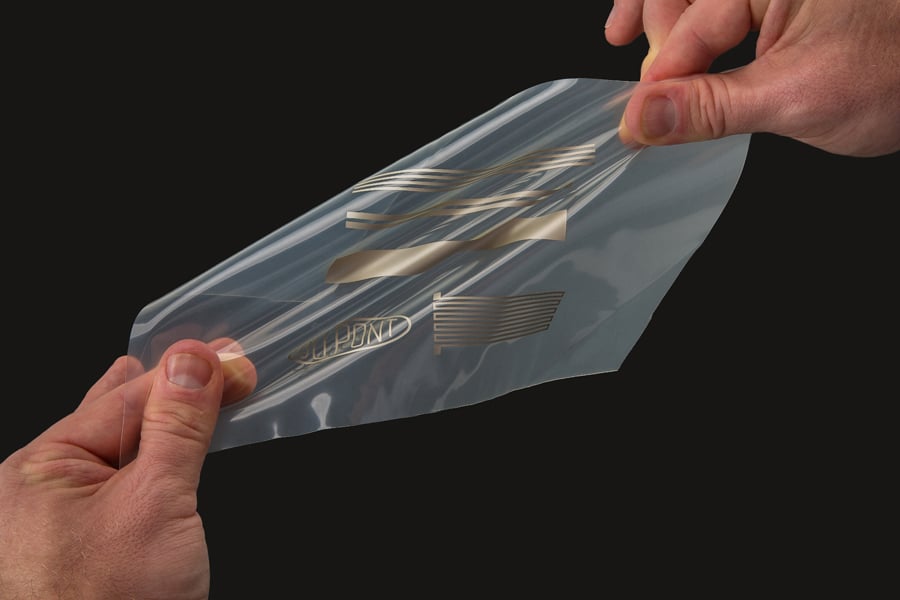

The high-tech film is hyper durable, easy to clean, and can be applied to almost any surface, increasing the life of materials while reducing contamination.

Sponsored by:

“On any one day I might find myself collaborating with customers about graphic signage, a facade system, or aircraft applications,” says Nathaniel Schwartz, a senior technical service consultant at DuPont. “The variety of different applications from just one product is highly unusual. It even has applications in outer space! The flexibility is really incredible.”

The product in question, Tedlar® polyvinyl fluoride film, is a type of invisible protective film that can provide durable, long-lasting protection to any number of physical surfaces. Best-known for its use in the manufacturing of back sheets for photovoltaic solar panels, it is also widely used in aerospace, for cabin interiors and insulation blankets. Despite these high-tech applications though, Schwartz is currently most excited by the impact of Tedlar® closer to home.

“We’re seeing increasing demand from architects and designers working on hospitals or on hospitality projects, such as hotels and restaurants,” he explains. “Tedlar® is perfect for interior wallcoverings and surfaces because of its extreme durability, cleanability and resistance to harsh chemicals. These qualities are more important than ever when creating highly cleanable spaces in a post-COVID world.”

Because it’s easy to laminate Tedlar® onto many different substrates—including PVC, metal, wood, and a wide variety of plastics. The film does not support the growth of mold or mildew, shows reduced bacterial growth, and can withstand the harshest chemical cleaning solvents, including bleach, alcohols, acids, and alkalis. For example, the whole product line is Class A rated for flame and smoke and Greenguard Gold certified by UL for improving indoor air quality by reducing volatile organic compounds.

“The terrible impact of COVID has led to a lot of customers coming to us with questions around viruses and bacteria and how this product behaves,” says Schwartz. “The most important thing we tell them is to clean and disinfect. The great news is that Tedlar® is tremendously compatible with pretty much any cleaning agent you can throw at it.” As the healthcare and hospitality industries react to COVID-19 with increased sanitation and cleaning, it’s more important than ever before to use durable materials that can stand up to repeated washings with bleach and other disinfectants. “We’re having conversations around new product concepts and leveraging our knowledge and understanding into new offerings that can help people at a time when rigorously cleaning many surfaces is essential, but often costly. Tedlar® is a highly durable value proposition that will save people money in the long run.”

The film, which is manufactured at plants in New York, and Ohio and comes in over 20 different colors, is distributed across North America, with DuPont eyeing expansion into Europe, the Middle East and Africa. China is an especially promising market, where Tedlar® has been a key component in several innovative construction projects.

At the recently completed six-story Changsha Guangxiu Hospital in Hunan, for example, nearly 60,000 square feet of Tedlar® Wallcovering was used in the public corridors and ward areas, including about 21,000 square feet of metal laminated panels that will endure for over three decades. In addition to satisfying the strict healthcare demands required by the hospital, the film was also chosen because it provides a warm and comfortable healthcare environment for patients while also being easy to scrub and sterilize.

On the back of projects like this, demand for Tedlar® is rising, and Schwartz is busy exploring yet more applications for the product. “It’s an exciting time,” he says. “We’re busy evolving how Tedlar® can be used in market sectors we’re already participating in, like ceiling tiles for example, while also embracing completely new areas for us, like cruise ships and marine applications.

“If we can find a better solution for an existing problem, or improve an existing product for a new problem, that’s huge,” he adds. “There’s really a lot of cool things we’re working on for the future, especially in healthcare environments.”

Recent Products

Products

What We Loved at ICFF 2025