November 12, 2012

Three Factors to Consider in Restoring Exposed Concrete

An irregular hairline crack in the concrete chimney of Le Corbusier’s Dominican Monastery of La Tourette (Éveux, France; completed 1960).From Walking through Le Corbusier by José Baltanás (London: Thames and Hudson, 2005), p16. More from Metropolis Our last post, “Materials and Building Components,” described modernism’s growing emphasis on monolithic concrete walls as an alternative to […]

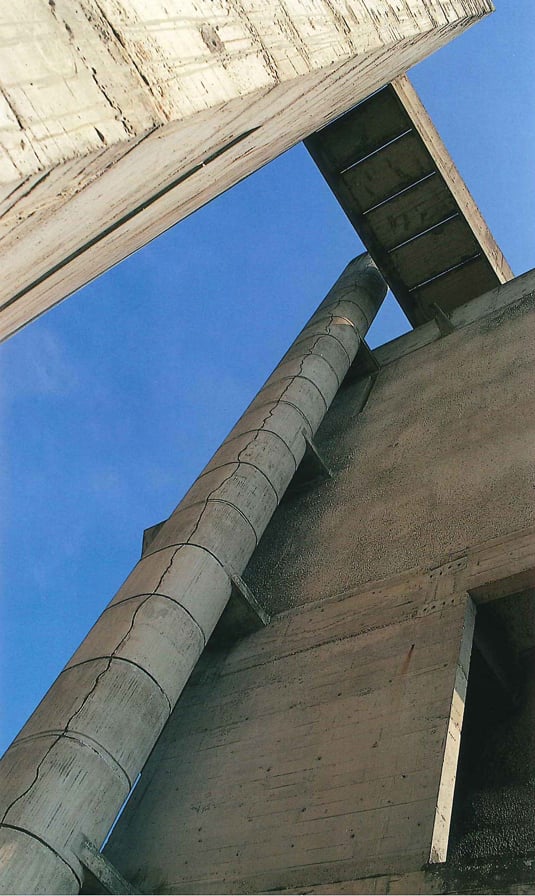

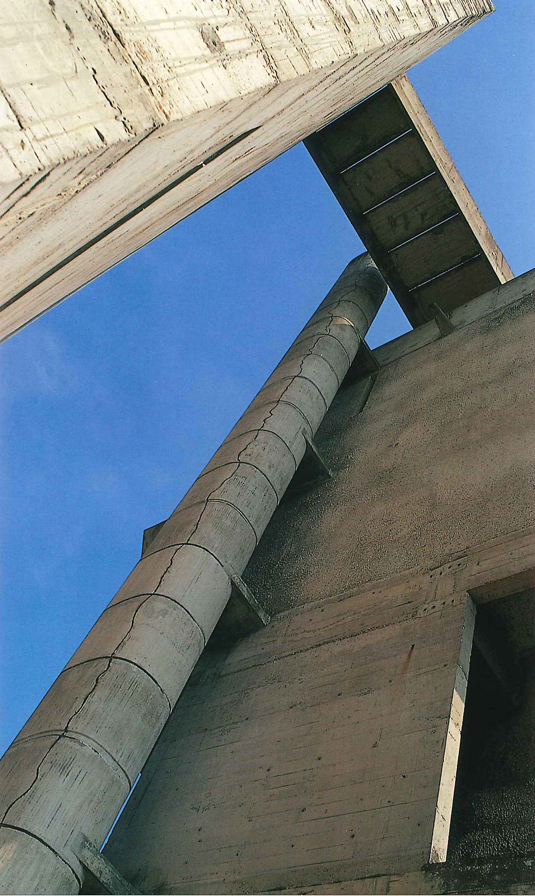

An irregular hairline crack in the concrete chimney of Le Corbusier’s Dominican Monastery of La Tourette (Éveux, France; completed 1960).

From Walking through Le Corbusier by José Baltanás (London: Thames and Hudson, 2005), p16.

Our last post, “Materials and Building Components,” described modernism’s growing emphasis on monolithic concrete walls as an alternative to traditional masonry. While conservation of brick and stone are now well understood, failures in exposed concrete are presenting new challenges, both technical and aesthetic. Monolithic concrete no longer has the same hold on the imaginations of architects as it did for the Brutalist masters, and technical difficulties have contributed to the demise of its popularity. Understanding how to preserve this honest, raw material is crucial to saving a seminal style from sure extinction.

Technical and Aesthetic Challenges

Mechanical failures showed up in mid-century concrete wall sections almost immediately, but the chemical changes that affect the walls’ integrity and longevity are more insidious and these were slower to emerge. The technical aspects of restoring concrete are especially challenging when compared with brick and stone, as concrete walls contain embedded steel, and steel’s corrosion can be destructive in many ways. Concrete restoration is also difficult aesthetically. Unfortunately today, the escalating default response for many building owners and their consultants is to apply elastomeric coatings over entire concrete facades, changing their appearance in a way that undermines the façade’s character and significance. Poorly conceived and executed repairs only amplify this trend.

Mechanical Failures

Physical changes in concrete over time contribute greatly to its ruin. Concrete shrinks and creeps. Concrete beams and slabs deflect. This movement causes cracks where water can penetrate to the reinforcing steel. Cast-in-place concrete wall sections are especially vulnerable to variations in the depth of cover at reinforcing steel, and water penetration need not be very deep to cause the corrosion that forces surfaces to spall.

Patch. Concrete spalls are replaced with composite mortar repairs in simple rectangles to be as unobtrusive as possible (1995 restoration at Josep Lluis Sert’s Peabody Terrace, Harvard University, built 1963). Photo courtesy Bruner/Cott.

Spall. Inadequate cover for reinforcing steel is the most frequent cause of spalled concrete in cast-in-place wall surfaces (Boston University School of Law, Josep Lluis Sert, completed 1964).

Courtesy Bruner/Cott

Visually, in situ repairs for these problems are tricky. The depth of spalls requiring patching can frequently vary on the same elevation. Differences in air entrainment and water content can affect the appearance of patches, and those from the same batch of mortar can cure to contrasting tonalities if the depth of the substrate varies. Patching decisions are complicated by the need to clean and seal historic concrete facades within the time limits set by the costly rentals of lifts as well as the costs of staging.

We are encountering examples of these challenges at the Boston University School of Law by architect Josep Lluis Sert, completed in 1964. The thin, projecting, precast fins have frequently failed there due to reinforcing steel set too near the concrete surface. Other projecting precast elements have crumbled at their upper corners because of prolonged wetting and frost action, even without associated steel corrosion. In situ repairs to both cast-in-place and precast surfaces can be very difficult—physically and visually. While such repairs are possible for crumbling concrete, when rebar is close to the surface in precast elements and the spall is significant, we try to replace the entire piece. Firms that produce architectural concrete are now able to make very convincing replicas of precast components with good visual matches to both the aggregate and the cement matrix.

Repair Cut- Spalling concrete is cut back to a uniform depth with excavation behind shallow rebars for a positive anchorage (1995 restoration of Josep Lluis Sert’s Peabody Terrace, Harvard University, built 1963).

Courtesy Bruner/Cott.

Chemical Deterioration

Concrete’s special complications most often arise from a combination of mechanical failure and the chemical reactions triggered by water penetration.

Water enters walls and slabs through cracks and honeycombed surfaces, which then spall. While new concrete is sufficiently alkaline to protect steel rebar and mesh from oxidation, moisture infiltration over time can generate a chemical reaction that reduces the pH of the concrete surrounding reinforcing steel. In fact, two of the three most common chemical failures of the material involve the loss of alkalinity, most often attributed to chloride contamination and the process of carbonation. There are several approaches used to address this problem. Electrochemical methods can restore the alkaline surround of embedded steel. Chloride ion extraction and re-alkalization are separate treatments that restore reinforcing steel to a passive state, but they do not last indefinitely. Furthermore, important concrete building facades are increasingly being preserved by permanent installations of cathodic protection that employs live low-voltage currents against corrosion.

A third type of deterioration, alkali silica reactivity (ASR), is a different problem, because it is independent of corrosion. Some aggregates contain silica compounds that react with alkaline cement to cause mineral transformations within the concrete matrix. Their reaction results in the physical change of aggregates to a silica gel that expands within the concrete, causing irreversible deterioration.

Chemical Failure

Alkali silica reactivity in a characteristic crazed pattern is apparent on an exposed concrete pier at John Andrews’s Harvard Graduate School of Design (completed 1971).

Courtesy Bruner/Cott

Analysis and Design

With the growing knowledge about concrete preservation in mind, owners and their architects can now design sensitive repair programs that solve concrete façade problems, with longevity and visual integrity that painting over badly applied patches cannot offer. Typically, this will involve laboratory analysis to determine what chemical processes are causing failures, how extensive these failures are within the façade, and how rapidly they will intensify. Needless to say, this conservation approach to the physical repairs will still require the eye and mind of an experienced architect. What are your thoughts about the processes we discuss here? We’d like to hear about your related experiences with them.

Our next post will address sustainability improvements and preservation logic for windows in mid-century modern buildings.

Henry Moss, AIA, LEED AP, is a preservation expert and principal at Bruner/Cott & Associates, a Cambridge, Massachusetts, architecture and planning firm.

Ken Guditz, AIA, LEED AP, is an associate at the firm, specializing in the restoration and adaptive reuse of historic structures of local and national significance.