October 17, 2024

Eight Building Products to Help You Push the Envelope

For its Products 2024 issue, METROPOLIS rounds up the best envelope-pushing building products for architecture and interiors.

ABOVE: LONGBOARD ECO

Producing aluminum from ore uses a lot of energy, but it is also one of the most easily recyclable metals. Longboard, a leading producer of aluminum cladding for buildings, is leveraging the circularity potential of the material to offer ECO, a suite of products with at least 50 percent recycled aluminum (the industry average is currently about 33 percent). This means embodied carbon savings of about 45 percent compared with standard aluminum products. ECO is also fully recyclable, VOC- and Red List–free, made using chrome-free pretreatment, and manufactured using hydroelectric power.

LONGBOARD

longboardproducts.com

CLIMAGUARD 55

Targeted at residential architects, builders, and owners trying to stay ahead of changing energy standards, ClimaGuard 55 coated glass offers superior solar heat gain performance among mid-range VLT glass products—it has a solar heat gain coefficient of 0.258, with a U-value of 0.243, and visible light transmission of 55 percent. Adding Guardian ClimaGuard IS 20 interior surface coating will improve those numbers even further. With this offering, Guardian Glass is trying “to help customers meet ENERGY Star Version 7.0 and other codes that drive energy conservation,” adds Suresh Devisetti, the director of product management.

Guardian Glass

guardianglass.com

RELIANCE-TC LT

For better thermal protection against climate extremes in the United States and Canada, Oldcastle BuildingEnvelope (OBE) has extended its Reliance range of curtain wall solutions with the slim Reliance-TC LT. With a two-inch sight line, this double-pane wall provides great seismic performance, is lightweight and cost-competitive, and performs at a U-factor level of 0.29, making it ideal for buildings in IECC Zones 4–8. “And because it comes from OBE, installers can enjoy the convenience of a single-source solution for both framing and glass,” says Julie Schessler, product manager at OBE. Reliance-TC LT is Red List–free.

OLDCASTLE BUILDING ENVELOPE

obe.com

STONE BRICKS

Stone company Borrowed Earth sees its raw material—stone from quarries in India, Iran, or Portugal—as merely “borrowed” from the planet. Founder and CEO Ruchika Grover understands a thing or two about that because her first job was as a block marker, selecting stone for her father’s marble and granite trade. The waste she saw in those quarries inspired Borrowed Earth’s latest offering—Stone Bricks made out of the remnants and discards from the process of cutting slabs and tiles. The bricks come in eight colors, and can be previewed in any configuration using the company’s AR app. “There are so many patterns and textures you can create with it,” Grover says.

BORROWED EARTH

borrowedearthcollaborative.com

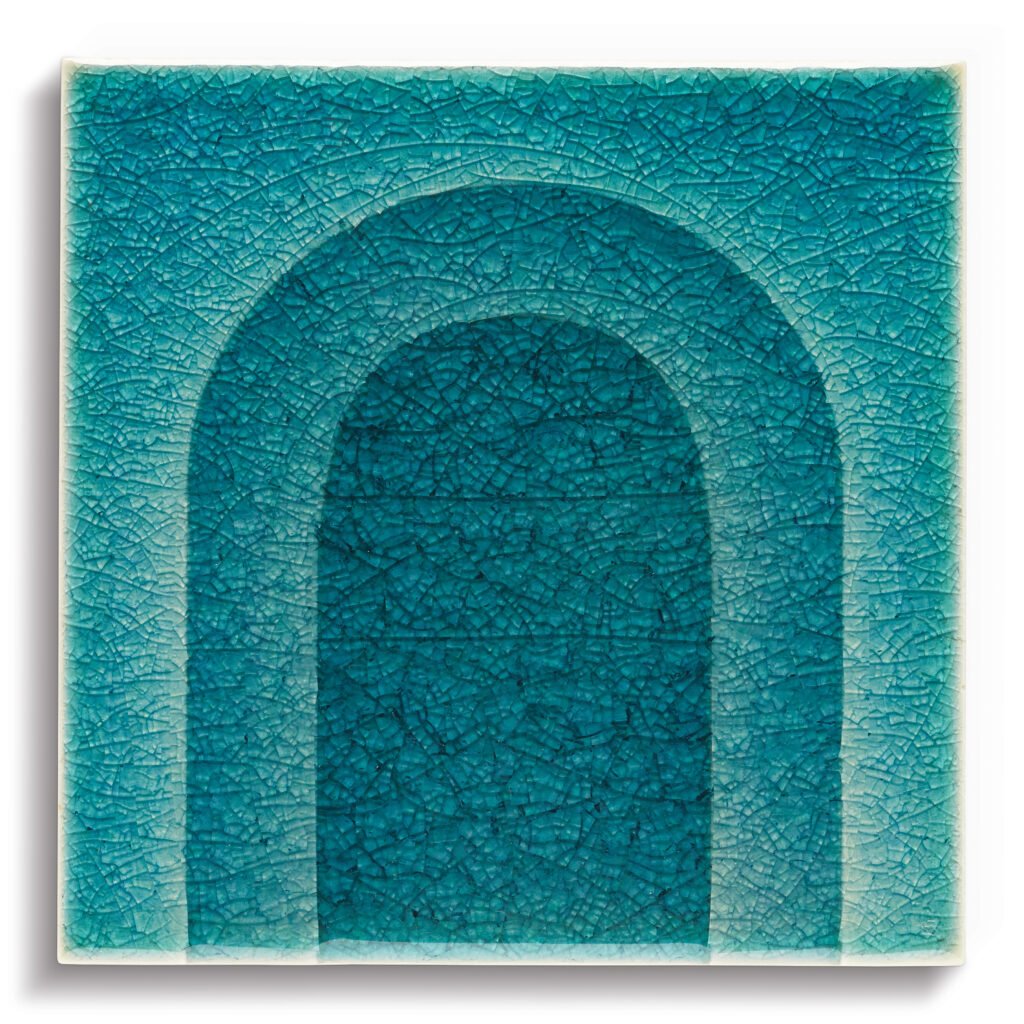

BLUE SMOOTH IRONSPOT

In addition to being an ancient building material and having many positive environmental impacts, brick today offers a mind-boggling array of aesthetic choices. Brick manufacturer Glen-Gery has so many options, in fact, that the company announces an annual Brick Color of the Year. 2024’s choice is Blue Smooth Ironspot, produced from the clay deposits of the Loess Hills in Iowa. “We foresee designers still having a desire to bring nature indoors but with a shift toward bolder colors, especially deep blue tones that add a fresh sense of tranquility,” says Glen-Gery’s marketing manager Denise Smith. Blue Smooth Ironspot is one of the company’s many brick lines that have a significant amount of pre-consumer recycled content, including sawdust, sludge, and metallic oxides.

Glen-Gery

glengery.com

CUPA PIZARRAS

While metals, ceramics, and plastics have all become popular cladding materials in recent decades, natural slate has been used on exterior walls for centuries. Extracted from the world’s largest tectonic slate reserves in Spain, Cupaclad slate rainscreen cladding systems are handcrafted, receive no chemical treatments, and are significantly more sustainable than other cladding materials—requiring a tenth of the energy needed to make clay facades, for example, and resulting in a fifth of the pollution caused by fiber cement manufacturing. The system is impact- and earthquake-resistant, and comes with an EPD and a carbon-neutral certification.

Cupaclad

cupapizarras.com

SECOND NATURE

The Charlotte, North Carolina–based window and door manufacturer Jeld-Wen has set two sustainability goals—using only fully recycled or harvested materials, and sourcing only sustainably certified wood for all its products. The Second Nature collection is in line with both goals. Recycled wood fiber (including waste from Jeld-Wen’s own mills) or wood fiber from FSC-, PEFC-, SFI-, or ATFS-certified forests make up 80 percent of all the content in every door. The solid-core construction of these doors means they transmit less sound and are extremely durable. Every offering in the Second Nature collection also comes with a five-year limited warranty.

Jeld-Wen

jeld-wen.com

250T/350T/500T INSULPOUR

As energy codes continue to get more stringent, and as buildings reach for higher efficiency goals, managing thermal performance becomes absolutely critical. “A lot of our R&D investment goes into understanding how thermal breaks can improve the performance of our products,” says Chris Shultz, Kawneer’s product manager for storefronts, entrances, and framing. The company’s Insulpour Thermal Entrances use new polymer isolator technologies within the tried-and-tested pour-and-debridge system to provide superior performance in commercial and multifamily buildings. When infilled with triple-pane insulating glass units, these entrances can provide U-factors as low as 0.42 BTU/hr./ft.2 /°F. Insulpour Thermal Entrances are Declare Red List–free and come with EPDs.

KAWNEER

kawneer.us

Would you like to comment on this article? Send your thoughts to: [email protected]

Related

Products

What We Loved at ICFF 2025

From B Corp rugs to furniture made from recycled styrofoam, ICFF 2025 was rich with sustainably designed furnishings, materials, and fixtures.

Products

How to Make Smart, Sustainable Surfacing Choices

Discover the latest information and offerings in this category to help you make beautiful, sustainable choices on your next project.

Products

Designing for Impact: CDW Product Awards 2025 Winners Announced

From sustainable textiles to workplace innovation, the inaugural CDW Product Awards honor standout designs shaping the future of interiors.