March 20, 2024

Mae-ling Lokko Designs from the Ground Up

“Ghana produces tons of chocolate, and the husk is the by-product, which is typically used for soaps,” the New Haven, Connecticut–based designer explains. “So we got a truckload delivered.”

Green shoots slowly began to emerge. “It got me thinking, how can something this valuable be free?” she says.

Since then, this question and Lokko’s refusal to fear failure have seen her take on some of Ghana’s major agricultural industries—from coconut water production to moringa and rice farming—to find sustainable design solutions. “The problems of one industry can usually only be solved when you connect them to the material life cycle of another sector,” says the designer, who holds a PhD and master of science in architectural science from Rensselaer Polytechnic Institute.

Lokko launched Willow Technologies in 2017 to advance the research and development of agricultural by-products and biomaterials into building technologies. Its creations include insulation panels made from coconut husks—a by-product of coconut water production and the cosmetics industry in Ghana—and wall panels made with mycelium, hemp, and kenaf fibers. “I started Willow Technologies to give myself the nimbleness to work with a range of international organizations,” she says.

Along the way she has coauthored “Building Materials and the Climate: Constructing a New Future” for the 2023 United Nations Environment Program global report on how to decarbonize the built environment; used indigenous rice plants and coconut pith in a bioswale to address flooding in an Accra, Ghana, park; and seen her material innovations exhibited around the world, including at New York’s Museum of Modern Art (MoMA) and Sweden’s Nobel Prize Museum. Visitors to MoMA’s exhibition Life Cycles: The Materials of Contemporary Design (on view through July 7), for example, will encounter a wall of her geometric mycelium panels, their rhythmic pattern and texture recalling woven textiles.

MoMA senior curator Paola Antonelli had been following Lokko’s work for years before she asked her to create the only specially commissioned piece for the show. “Mae-ling has devised many effective and elegant ways to transform agro-waste into building materials that continue the cycle of life as opposed to interrupting it—and redistribute value,” she says. “I like her pragmatism—the fact that she is not only making compelling objects and testing new processes but also demonstrating the viability of a new model of entrepreneurship through Willow Technologies.”

One of Lokko’s goals is to drive “generative justice” through her work by developing fresh models for distributed production and collaboration. “At Willow Technologies we ask ourselves, how do we design infrastructures that can allow agro-waste to be collected and processed close to where it’s produced?” she says. “And how do we bring in stakeholders who have been left out of the eco-manufacturing framework?”

Such questions were at the heart of her investigation into Ghana’s booming coconut industry. Discarded husks pile high in neighborhoods across Accra—a problem for traders and the city’s residents alike. “They can’t dump the husks in municipal waste systems because they’re too heavy, so I followed the coconut traders at night to see how they get rid of them,” she explains. She discovered that once a week they pile the husks in empty lots and burn them quickly to ensure they don’t get caught.

“I thought to myself, if we can give them the infrastructure to shred the husks each day and they can be remunerated for preprocessing them, then we could solve a huge burden for them, get a higher-quality material [that hasn’t been contaminated on the streets], and create allies in transforming the waste in our cities,” she adds.

Lokko spent a year mapping coconut traders across Accra and prototyping a milling machine while designing new applications for the husks as high-value building materials. But she soon hit obstacles. “There are barriers to where you can place them, because you’re dealing with private land,” she says. “So I went back to the drawing board.”

The designer is now working to encourage both top-down and bottom-up collaboration in Ghana. “From a policy perspective, I’m trying to figure out how we can start integrating these machines into markets where there’s already food production, and close to businesses that have a waste problem,” she explains. Designing the technology isn’t hard, Lokko adds; the challenge is deducing “where to put the infrastructure, who owns it, and how do you ensure it will be maintained.”

Lokko’s undulating panels of thermally pressed coconut husks were exhibited as part of Grounds for Return, her first solo show at Brussels’s Z33 House for Contemporary Art, Design, and Architecture in 2022.

Grounds for Return explored the cycle in which crops and dwellings sprout from the earth and can restore life to the land and its people through their growth and eventual decay. The visitor’s journey began with a threshold framed by the panels that took cues from the “doors of no return” found in castles along the West African coastline, an enduring symbol of the forced transportation of enslaved people.

“My installations often reference architecture associated with extraction,” Lokko explains. In this case she means human labor. “It’s important to connect the material economy with the decolonial project because materials and the aesthetics around them are caught up in so much politics.” Elsewhere tunnels of mycelium panels recalled mines and the exploitation of the earth.

In the States, Lokko sources agro-waste and mycelium from New York–based materials company Ecovative to create architectural forms. Her wall panels for MoMA were made by milling hemp and kenaf fibers, then injecting them with mycelium to form a substrate that is packed by hand into custom-designed grow trays. It takes an average of five days for the mycelium to digest all the sugars to create a low-density but compact, off-white micro composite, which can be dried in the sun or an oven to prevent fruiting mushroom bodies. These components can then be assembled into a structure.

Lokko will be taking this work in a fresh direction this spring, developing a cotton-fed mycelium installation for the Dakar Biennale, opening in May. But as demand for biomaterials grows, Lokko acknowledges that we need to tread carefully.

“If we’re reliant on one mycelium strain and the by-products of agricultural monocultures, then the paradigm hasn’t shifted in terms of production,” the architectural scientist explains. “We need to pay attention to seasonality and a range of crops, exploring ways to mix and match.” If we don’t, she adds, we risk exacerbating biodiversity loss.

These are issues she debates with her students at Yale, where she teaches topics including environmental design and material design for soil health. In late 2024, however, she is taking a sabbatical from teaching to write a book. “I’ve been trying to reconcile my work with biobased materials with my interest in the history of the transatlantic slave trade,” she says.

The book will connect the dots between the big super crops—sugar, rice, corn, and wheat—and the labor systems that have surrounded them throughout history, while also exploring today’s agricultural giant, the soybean. “These are our only models for scaling biomaterials, and they offer cautionary tales,” she says. “We need to look to history to avoid the unanticipated consequences of environmental and social inequity.”

Lokko’s work lays bare both the potential and challenges of using biomaterials in the built environment. As populations swell and the construction world grows ever hungrier, we’d be wise to take heed.

Would you like to comment on this article? Send your thoughts to: [email protected]

Related

Products

4 Exciting New Possibilities for Concrete

The next generation of carbon-neutral and recycled concrete products is bringing foundational change to the world’s most common building material.

Viewpoints

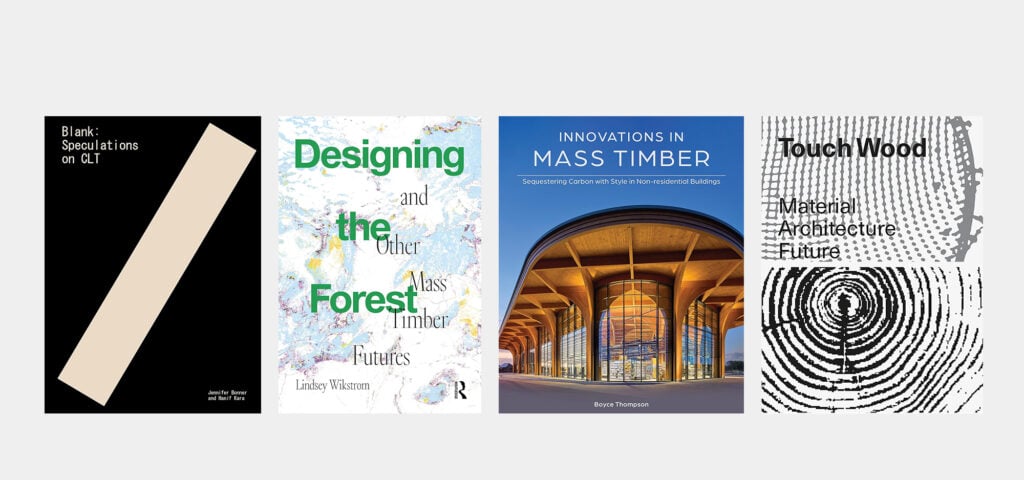

Put These Timber Architecture Books on Your Shelf

Four recent titles highlight the past and future of timber architecture, from forest to building products.

Profiles

Colombia’s Fundación Organizmo Builds for Planetary Well-being

The Bogota-based organization was recently awarded a Practice Lab grant from the architecture philanthropy platform re:arc institute.